During the days of my high school and college education, I did amateur jobs in McDonald’s, Sanyo, and other small enterprises that produced household items to compensate my fees. I began my professional career in Beko, a corporate company which operates internationally. I worked at other companies that were global and corporate afterwards. The ones that are not corporate were at least aiming to become one.

During my employment I’ve had a chance to get to know a lot of countries, corporations, and working cultures. I personally experienced businesses that scaled from a workplace in a cellar that produced ventilating fans from a one plastic enjection machine in Istanbul, Sefakoy to a Airbus A380 factory in France, Toulouse that built worlds largest airliners. Therefore, I’ve had a chance to observe every inch of the production plants that required powerful and cooperative teamwork to operate.

Interestingly enough, all of these operations had one common problem, which was internal friction, regardless of their final product and scale. In engineering, the term internal friction symbolizes the energy that is wasted or lost. In other words, the more a machine has internal friction, the less output it has.

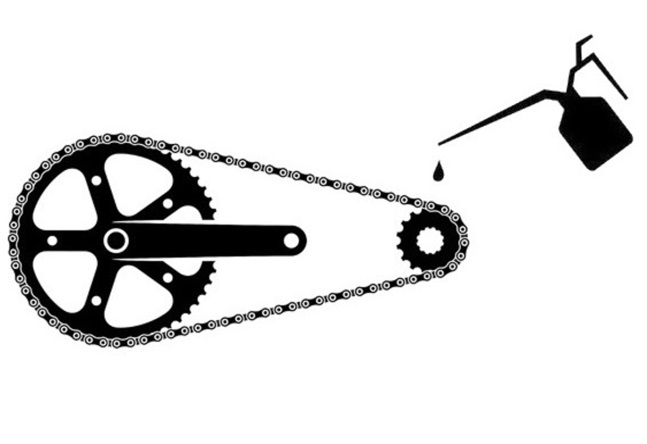

To give a simple example, people who rode classical bicycles before bicycles with gears were invented will remember, it’s not easy to cycle if the chain is rusted or dirty. Therefore we wouldn’t be able to ride fast and we’ll make a lot of noise whilst riding. The chain jams frequently and the pedals get stuck. As a matter of fact, sometimes the chain slips, and we’ll have to stop and fix it, get our hands dirty and can’t carry on. All this fuss and discomfort arises because of the increased internal friction of the bicycle. It’s not possible to cycle fast and comfortly in that situation no matter how hard we try. We can’t focus on the road properly because we’ll have to focus on the bicycle itself continually. Hence we’ll cycle over potholes, scrape ourself with the surroundings and add more to our substantial problems. Top of it all is the strange looks from people around us because of the noise, the ride becomes a torture. And we’ll be late to our destination.

The bicycle chain doesn’t consist of one piece because of its structure; it has a closed design with no beginning or an end, and all of the parts are clamped together. All of the parts have the same importance and if it’s not attached to the next piece (the infamous weakest link) the chain will get inefficient.

Just the contrary; namely when every part of the chain clasps together properly and it’s greased sufficiently, efficiency becomes maximum. Even when the bicycle goes really fast, it almost makes no sound. The pedals won’t get stuck and apart from unusual situations the chain won’t slip. The effort we spend to ride the bicycle will be reduced, and a fast and comfort ride will be possible. The bicycle won’t have a problem, therefore we’ll be more focused on the road and will be aware of our surroundings. Hence, we’ll arrive at our destination at designated time.

Similarly, no matter what the scale of an enterprise is, the problem is always the same. The scale of the enterprise only effects the length and the width of the chain of the bicycle example given; because logic of operation is the same, the solution of the problem is the same.

The internal friction of enterprises corresponds the communication between employees. The more insufficent, limited and one way the communication is, the more the friction increases. In contrast, the richer, liberated and multi directional the communication is, the capability of employees to work together in harmony increases in the same ratio.

The solution to reduce internal friction of the bicycle is to grease the chain appropriately. For the companies it is to give proper trainings and ethical practices that enrich, liberate and multi-direction the internal communication.