What are the items that make up the price of the plane ticket we buy?

There are a lot of components, no doubt. We can collect roughly under the following headings:

– Base fare

– Taxes and airport fees

– Fuel

– Service fee (agency commission)

– Food

– Seat selection

– Baggage

– Profit (inevitably)

It is possible to understand items other than base price.

So what’s in the “base price”?

That’s where the airline has all the costs.

– Lease payment or yield of depreciation

– Pilots’ fee

– Cabin crew fee

– Support staff’s fees

– Maintenance costs

– Other minor costs

When we open up maintenance costs a little more, we have the following main items:

– Rental fee for the hangar or ramp where the aircraft or engines are maintained

– Fees of maintenance staff

– Cost of maintenance equipment

– Charges of consumables/expandables used

– Replacement or repair of spare parts fees

– Rental or purchase fees of required special tools/equipment (if any)

How much does an average maintenance event cost? It varies according to the age of the aircraft and the scope of the maintenance.

Airliners are usually taken into maintenance every 18 to 24 months. Maintenance costs are rising as planes get older. Also 5th/6th, 10th/12th and 18th/20th years of the aircraft in service are the years require much wider scope of maintenance than usual so they are more costly. Just to have an idea, we can make an estimated, rough calculation, with certain assumptions.

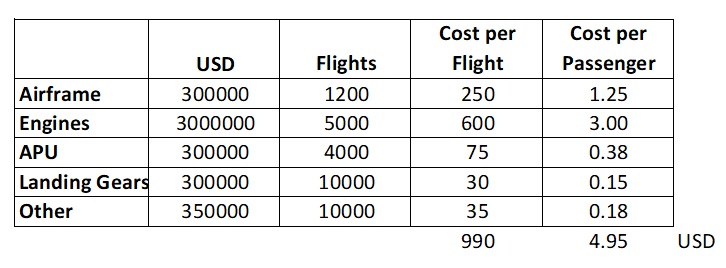

Routine maintenance of a 200-seat aircraft airframe can cost 300000 USD. Let’s consider that the same aircraft had a total of 1200 flights until the subjected maintenance.

Engines are repaired and serviced in a dedicated engine shop. They are without doubt the most costly maintenance activity of the airplane. Each engine, in a standard operation and condition, goes to the shop every 4 to 5 years, which is around 4000-5000 flights. Their final bill for both engines, together, is around USD 3M.

Auxiliry Power Unit, a small jet engine which is called APU, is also helps an airplane to run their systems and air conditioning, water, etc. This little spare engine also needs a periodic maintenance and it is sent to its special shop every 3-4 years. Each time, around USD 300K bill appears.

Landing gears as well are maintained in dedicated workshops and they usually born USD 300K bill for 10000 flights.

We also have some unpredicted failures, faults, need of fresh paint or interior improvements. Let’s put another USD 350K for these items for 10000 flights.

Of course, these numbers are round, rough or estimated figures. They do not reflect any kind of airplane or brand. They are here only to give us an idea, about the level of the maintenance cost in our airfare.

When we combine all these costs, in accordance with their respective ratio per flight, we have the following figure:

Around 5 USD of our ticket is used for the maintenance of the airplane. It is important to remember that we assumed there are 200 passengers per flight, and our aircraft is fully-occupied in its each flight. Of course, this is not the case even for the most assertive airline business model, like Ryan Air. An optimistic 80% occupancy rate will add 20% more maintenance cost per ticket.

In conclusion, around 6 USD of every ticket we buy is spent for the maintenance of the aircraft.